推荐消息更多>>

推荐消息更多>>气力输送系统设备的优势有哪些?

- 来源:/ 日期:2023-10-22 发布人:admin

在处理大量散装物料时,气力输送的效率相对较高。气力输送系统设备一般用于输送颗粒/粉末,这些颗粒/粉末由在传输线中移动的气流输送单元装载。气动输送机的一般工作原理是传递气流的动能。由于空气是清洁能源,系统在完全封闭的环境中工作,物料损耗和环境污染降到低,运输运行一般为零损耗。

When handling large quantities of bulk materials, the efficiency of pneumatic conveying is relatively high. Pneumatic conveying system equipment is generally used for conveying particles/powders, which are loaded by airflow conveying units moving in the conveying line. The general working principle of pneumatic conveyors is to transfer the kinetic energy of the airflow. Due to the fact that air is a clean energy source and the system operates in a completely enclosed environment, material loss and environmental pollution are minimized, and transportation operations are generally zero loss.

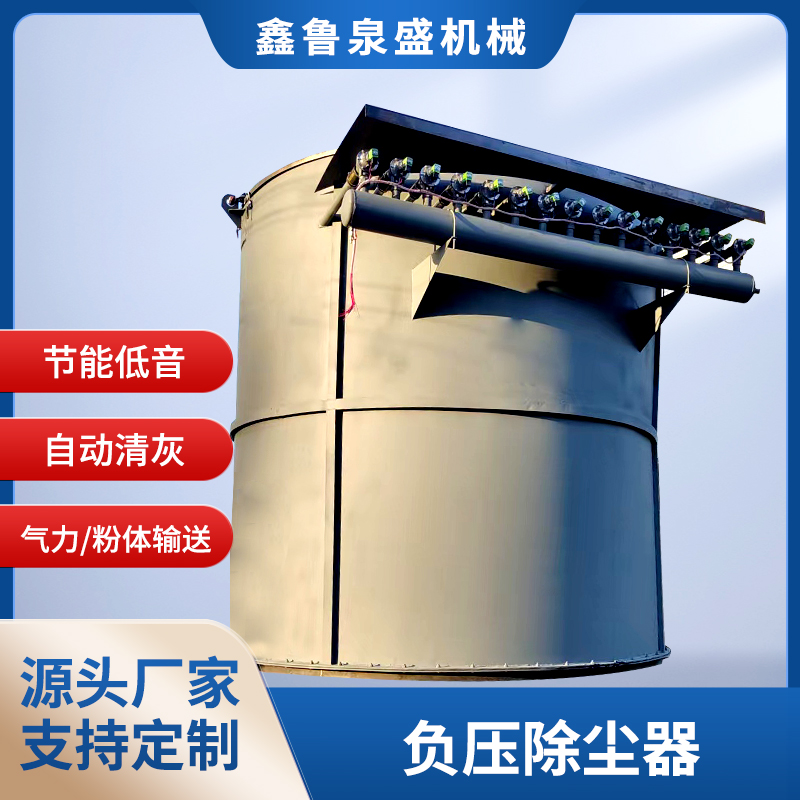

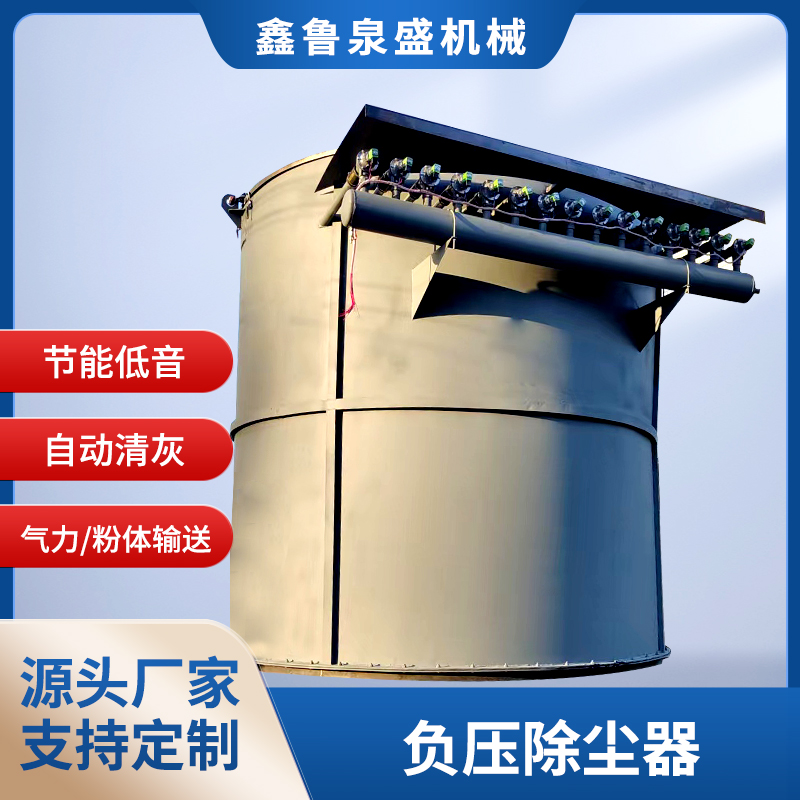

当获得和使用压缩空气时,气力输送系统设备中的许多地方都可能发生能量损失。通过对节能预防措施的综合研究,可以避免这些损失,显著降低能耗。由于气力输送系统的能源成本超过总成本的一半,气动应用的设计考虑了效率和节能,初期投资成本可在短时间内收回。常用的气力输送方式有:浓相气力输送系统、稀相气力输送系统、正压气力输送系统和负压气力输送系统。

When obtaining and using compressed air, energy loss may occur in many parts of the pneumatic conveying system equipment. Through comprehensive research on energy-saving prevention measures, these losses can be avoided and energy consumption can be significantly reduced. Due to the energy cost of the pneumatic conveying system exceeding half of the total cost, the design of pneumatic applications considers efficiency and energy conservation, and the initial investment cost can be recovered in a short period of time. The commonly used pneumatic conveying methods include: dense phase pneumatic conveying system, dilute phase pneumatic conveying system, positive pressure pneumatic conveying system, and negative pressure pneumatic conveying system.

气力输送系统设备的优点;

Advantages of pneumatic conveying system equipment;

并且安装和维护工作简单。

And the installation and maintenance work is simple.

提供灵活的设施。系统中使用的传输线可以很容易地适应工厂的布局,并在无尘的环境中工作,因此可以很容易地将材料输送到几乎所有的方向。

Provide flexible facilities. The transmission lines used in the system can easily adapt to the layout of the factory and work in a dust-free environment, making it easy to transport materials to almost all directions.

在气力输送系统设备运输过程中,材料损失和环境污染保持在低水平。

During the transportation of pneumatic conveying system equipment, material loss and environmental pollution remain at a low level.

提供灵活的转移操作,物料可以从一个点转移到另一个点或几个点。

Provide flexible transfer operations, where materials can be transferred from one point to another or several points.

考虑到机械输送机的承载能力,比机械输送机占用空间少。

Considering the carrying capacity of mechanical conveyors, they occupy less space than mechanical conveyors.

气力输送系统设备安全级别高。这是一个封闭的系统,人不会接触到机械传动系统,所以工业事故可以降到低。

The safety level of pneumatic conveying system equipment is high. This is a closed system where people do not come into contact with the mechanical transmission system, so industrial accidents can be minimized.

- 上一篇: 仓顶除尘器与仓顶除尘设备组成的粉料储存库

- 下一篇: 三叶罗茨风机使用的工作原理

扫码微信沟通

扫码微信沟通