推荐消息更多>>

推荐消息更多>>脉冲除尘器的工作原理介绍

- 来源:/ 日期:2023-10-05 发布人:admin

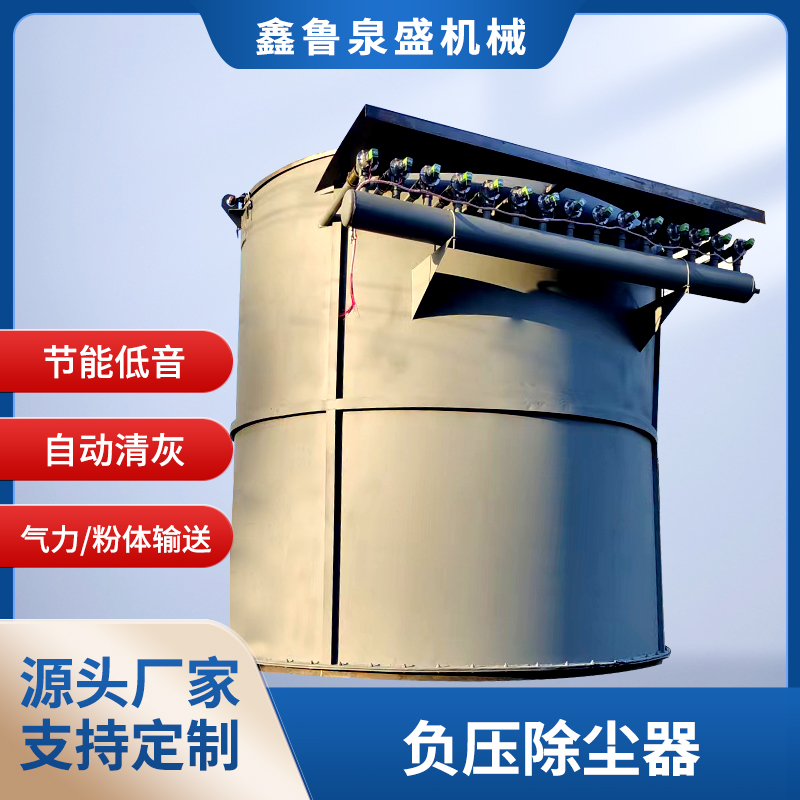

脉冲除尘器是一种高效的空气污染控制设备,主要用于工业领域的粉尘处理。它通过脉冲喷吹清洁技术,能够有效地去除粉尘颗粒,减少工业生产过程中对环境的污染,保护人类健康,并提高产品质量。

Pulse dust collector is an efficient air pollution control equipment mainly used for dust treatment in the industrial field. It can effectively remove dust particles, reduce environmental pollution during industrial production, protect human health, and improve product quality through pulse jet cleaning technology.

脉冲除尘器的工作原理是将沉积在滤袋上的粉尘颗粒利用高压风扇喷吹下来,再通过输送系统输送到粉尘仓中,最后通过排放口排放出去。其工作过程包括清洗阶段和吸尘阶段。清洗阶段是指滤袋中的风力喷射气流将附着在滤袋上的粉尘颗粒抖落下来,脉冲除尘器,脉冲除尘器价格,脉冲除尘器厂家从而实现滤袋的清洁;吸尘阶段是指进料系统将产生的废气引入脉冲除尘器内,经过脉冲喷射,使粉尘颗粒被清除,净化后的气体经过排气管排放出去。

The working principle of a pulse dust collector is to use a high-pressure fan to blow down the dust particles deposited on the filter bag, then transport them to the dust bin through the conveying system, and finally discharge them through the discharge outlet. The working process includes the cleaning stage and the vacuum stage. The cleaning stage refers to the process where the wind jet airflow in the filter bag shakes off the dust particles attached to the filter bag, and the price of the pulse dust collector and pulse dust collector are determined by the manufacturer to achieve the cleaning of the filter bag; The dust suction stage refers to the introduction of waste gas generated by the feeding system into the pulse dust collector, which is then pulsed to remove dust particles. The purified gas is then discharged through the exhaust pipe.

脉冲除尘器具有许多优点。首先,它的除尘效率高,能够去除微小的粉尘颗粒,使废气达到国家排放标准。其次,它可以处理大风量的废气,适用于各种工业生产环境。再次,由于采用了脉冲喷吹清洁技术,可以延长滤袋的使用寿命,降低了维护成本。此外,脉冲除尘器还有自动控制系统,可以根据实际情况进行调节,保证除尘效果和设备的安全运行。

Pulse dust collectors have many advantages. Firstly, its dust removal efficiency is high, which can remove small dust particles and make the exhaust gas meet national emission standards. Secondly, it can handle high air volume exhaust gas and is suitable for various industrial production environments. Once again, due to the use of pulse jet cleaning technology, the service life of the filter bag can be extended and maintenance costs can be reduced. In addition, the pulse dust collector also has an automatic control system that can be adjusted according to the actual situation to ensure the dust removal effect and safe operation of the equipment.

脉冲除尘器的应用范围非常广泛。它可以在钢铁、建材、化工、矿山等行业中用于处理各种烟气、尘气、废气。在钢铁行业中,脉冲除尘器被广泛应用于高炉、烧结机、炼钢厂等设备的烟气处理。在建材行业中,它可以应用于水泥炉、石膏炉等设备的尘气处理。在化工行业中,脉冲除尘器可以处理化工生产中产生的废气,减少对环境的污染。在矿山行业中,脉冲除尘器可以应用于矿石破碎、磨矿等环节的尘气处理。

The application range of pulse dust collectors is very wide. It can be used in industries such as steel, building materials, chemical, mining, etc. to treat various types of smoke, dust, and exhaust gases. In the steel industry, pulse dust collectors are widely used for flue gas treatment in equipment such as blast furnaces, sintering machines, and steelmaking plants. In the building materials industry, it can be applied to dust and gas treatment of equipment such as cement furnaces and gypsum furnaces. In the chemical industry, pulse dust collectors can treat the waste gas generated in chemical production, reducing environmental pollution. In the mining industry, pulse dust collectors can be applied to dust and gas treatment in processes such as ore crushing and grinding.

总之,脉冲除尘器是一种高效、节能的空气污染控制设备。它通过使用脉冲喷吹清洁技术,能够有效地去除粉尘颗粒,净化废气,保护环境,提高产品质量。脉冲除尘器的广泛应用,使得各行各业都能够在生产中更好地控制污染,实现可持续发展。随着科技的不断进步,脉冲除尘器的性能将会不断提高,使得其在环保领域发挥更大的作用。

In short, pulse dust collectors are an efficient and energy-saving air pollution control equipment. It can effectively remove dust particles, purify exhaust gas, protect the environment, and improve product quality by using pulse jet cleaning technology. The widespread application of pulse dust collectors enables various industries to better control pollution in production and achieve sustainable development. With the continuous progress of technology, the performance of pulse dust collectors will continue to improve, making them play a greater role in the field of environmental protection.

- 上一篇: 降低罗茨鼓风机的阻力的方式

- 下一篇: 旋转供料器的正确的安装方法

扫码微信沟通

扫码微信沟通